We produce a lot of sheet metal work using invento and use 0 2732 for below 3mm sheet and 0 3365 for 3mm and above using ilogic we automatically set the k factor depending on the thk of material so we don t forget to adjust it each time.

Catia sheet metal k factor.

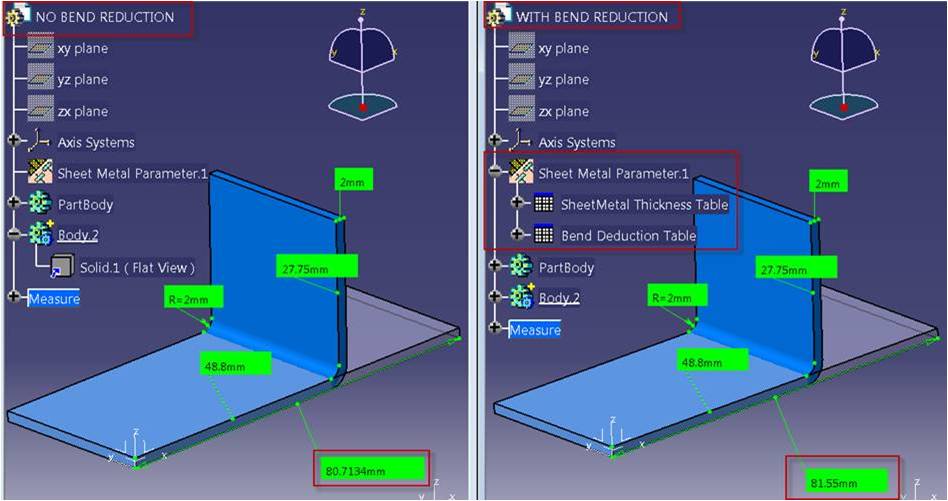

Sheet metal depends on certain parameters 1 thickness 2 bend radius 3 bend angle.

Cad tools use k factor to calculate sheet metal blank size.

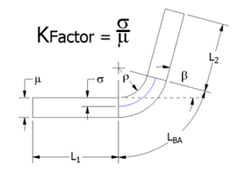

K t t why the k factor cannot exceed 0 5.

L ᴫ 2 r y t θ 90.

To calculate the bend allowance the k factor and the derived coefficient called the y factor insert the thickness and initial length of the sheet into the cells on the left.

Definition of the k factor.

Best way to calculate k factor in sheet metal is by reverse engineering.

Our design engineers typically use a factor of 0 4 for our air formed press brake parts.

From this video will we start catia v5 generative sheet metal design tutorials series.

1 introduction sheet metal introduction 2 primary walls and secondary walls 3 sheetmetal parameters 4 k factor and y factor 5 various sheet metal tools 6 creating sheet metal components.

Value of k factor is always less than 0 5.

When you bend sheet metal the neutral axis shifts toward the inside surface of the bend.

The k factor in sheet metal working is the ratio of the neutral axis to the material thickness.

The line where the transition from compression to stretching occurs is called the neutral axis.

Bending angle is 90.

The k factor is the ratio of the neutral axis location t to the material thickness mt.

Catia an acronym of computer aided three dimensional interactive application in english usually pronounced multi platform computer aided design cad computer aided manufacturing cam.

You can also use our flat pattern calculator for blank size calculation.

The k factor is the ratio of the neutral layer position thickness t of the sheet metal to the overall thickness of the sheet metal material t i e.

Value of the k factor depends on material bend radius sheet thickness and machines used.

When metal is bent the top section is going to undergo compression and the bottom section will be stretched.

You can use this k factor calculator to calculate k factor using reverse engineering method.

Mathematically k factor is a ratio of position of neutral axis and sheet thickness.

K factor is a constant used to calculate the sheetmetal flat length.

Catia sheet metal tutorial for beginners.

After bending the sheet insert the inner radius and flanges a and b.

In this tutorial you will le.